Product Description

Aluminum Pin Lug Pipe Connectors Short Shank Suction Coupling

Pin Lug:

Specifications

Aluminum Pin lug coupling

Swivel nut coupling

Suction Hose Fitting

Sizes: from 1″ to 8″

Parts: Full set. Female, Male. Brass nut

Pin lug coupling (Swivel nut coupling. Vapour Recovery)

Sizes:

From 1″,1-1/2″ .2″. 2-1/2″.3″.4″.5″.6″

Parts:

Full set

Female set

Male set

Brass nut

Body material:

Aluminum body with brass nut

Advantage:

safe, fast, easy to operate

Thread:

NPSH, NST

Usage range:

can be used for water, oil or other liquid, but not for air or gas applications

Package:

standard paper carton, and then packed by pallets

Our Service:

1. provide OEM, ODM, OBM service;

2. provide after sales service.

3. supply one-stop service

FAQ:

1. Are you a factory or a trading company?

We guarantee that we are a manufacturer of PVC hoses,coupling, your visit will be highly appreciated!

2. What are you offering?

1) PVC hoses (layflat hose, suction hose, braided hose, garden hose, air hose etc.)

2) Hose couplings and clamps

3) Garden equipment

3. Can your company supply some certificate for your product or can you accept some test for your product or your company?

Yes, we had passed a lot of test for our product and factory and factory. Any testing can make by your need.

4. What’s your advantages?

CHINAMFG is a trusted professional hose manufacturer, we have more than 20 years of production experience.

We own 80 production lines to make sure good quality hose and fast delivery time.

We promise to provide professional after-sales service, solve all kinds of technical problems at any time until customer satisfy.

We have join Alibaba trade assurance (a free payment protection service), payment more sa

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Connection: | Male / Female |

|---|---|

| Structure: | Universal |

| Flexible or Rigid: | Rigid |

| Material: | Aluminium, Brass, Stainless Steel, PP, Nylon, Iron |

| Standard: | Standard |

| Product Name: | Pin Lug |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

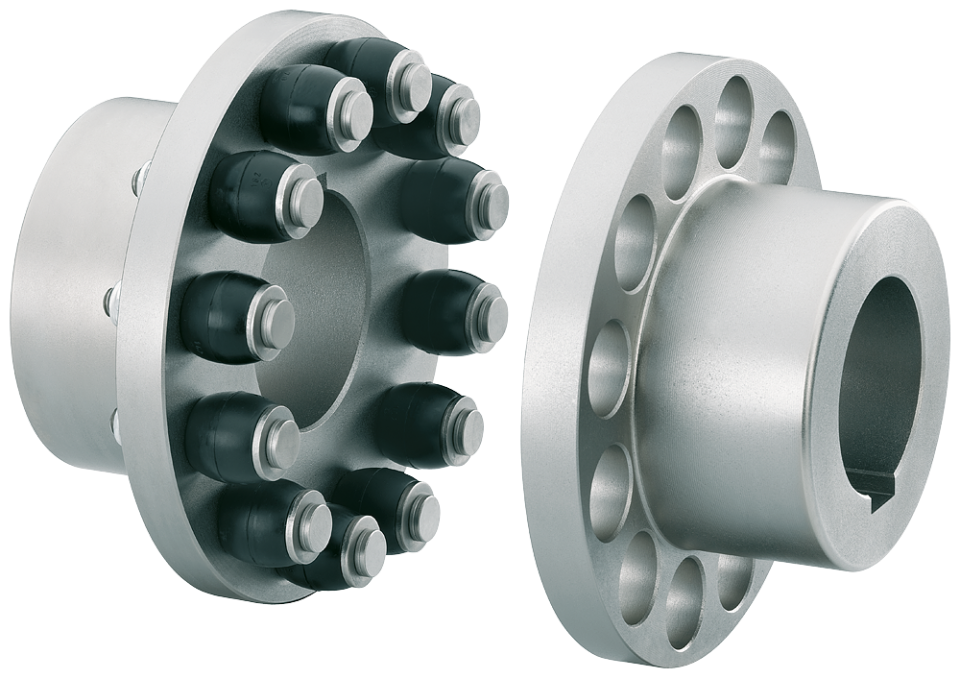

Can Pin Couplings Be Used in Both Horizontal and Vertical Shaft Arrangements?

Yes, pin couplings can be used in both horizontal and vertical shaft arrangements. These couplings are designed to accommodate angular misalignment, parallel misalignment, and axial movement, making them versatile for various shaft orientations.

In horizontal shaft arrangements, where the shafts are aligned on the same horizontal plane, pin couplings can efficiently transmit torque while allowing for flexibility to accommodate minor misalignments and shaft movements. The pins and flexible elements in the coupling enable angular displacement and radial flexibility, ensuring smooth power transmission even if the shafts are not perfectly aligned.

In vertical shaft arrangements, where the shafts are aligned on a vertical plane, pin couplings can also be used effectively. The coupling design allows for axial movement, which is crucial in vertical applications where the shafts may experience expansion or contraction due to thermal changes or other factors. The flexible nature of pin couplings allows them to handle these axial movements without compromising the coupling’s performance.

Whether in horizontal or vertical arrangements, pin couplings are commonly used in various industrial applications, including pumps, compressors, conveyors, and other rotating machinery. They are known for their simplicity, ease of installation, and ability to provide reliable power transmission while accommodating misalignment and shaft movement.

When using pin couplings in either arrangement, it is essential to ensure proper alignment and regular maintenance to maximize their performance and service life. Additionally, considering factors like torque requirements, operating conditions, and environmental considerations will help in selecting the appropriate pin coupling for a specific application.

Factors to Consider When Choosing a Pin Coupling for a Specific System

When selecting a pin coupling for a specific system, several critical factors need to be considered to ensure optimal performance, reliability, and longevity. Each application has unique requirements, and choosing the right pin coupling involves assessing the following factors:

1. Torque and Power Requirements: Determine the torque and power transmission requirements of the system. The pin coupling must be capable of handling the maximum torque and power generated by the connected equipment.

2. Operating Speed: Consider the rotational speed of the system’s driving and driven shafts. The pin coupling’s design should allow for smooth and efficient operation at the specified speed range.

3. Misalignment Tolerance: Assess the degree of misalignment between the shafts that the coupling needs to accommodate. Pin couplings are suitable for applications with moderate angular, parallel, and axial misalignment.

4. Operating Environment: Consider the environmental conditions the coupling will be exposed to, including temperature, humidity, dust, and presence of corrosive substances. Choose a pin coupling with materials and surface treatments suitable for the operating environment.

5. Size and Space Constraints: Ensure that the selected pin coupling fits within the available space and does not interfere with other components in the system.

6. Serviceability and Maintenance: Evaluate the ease of installation, maintenance, and replacement of the pin coupling. Easy-to-service couplings can help reduce downtime and maintenance costs.

7. Shock and Vibration: Consider the level of shock and vibration the system will experience. The pin coupling should be robust enough to handle these dynamic loads without failure.

8. Cost: Evaluate the overall cost of the pin coupling, including its initial purchase price, maintenance costs, and potential downtime expenses. Choose a coupling that offers the best balance of performance and cost-effectiveness.

9. Material Selection: Select the appropriate materials for the pin coupling based on the application requirements. Common materials include carbon steel, stainless steel, and alloy steel.

10. Compatibility: Ensure that the pin coupling is compatible with the specific shaft sizes and configurations of the system’s driving and driven components.

11. Compliance with Industry Standards: Check if the pin coupling meets relevant industry standards and safety requirements.

By carefully considering these factors, engineers and system designers can choose the most suitable pin coupling for their specific application. It’s essential to work closely with coupling manufacturers or suppliers to ensure that the selected coupling meets all the necessary specifications and requirements.

Advantages of Using Pin Couplings in Mechanical Systems

Pin couplings, also known as shear pin couplings, offer several advantages when used in mechanical systems. These advantages make them a popular choice for various industrial applications:

- 1. Overload Protection: Pin couplings are designed to provide overload protection to connected equipment. In case of excessive torque or sudden shock loads, the sacrificial pins will shear off, preventing damage to the shafts and other components.

- 2. Misalignment Tolerance: Pin couplings can accommodate a limited amount of angular misalignment between the shafts. This helps to compensate for minor misalignments and reduces the stress on the connected equipment.

- 3. Cost-Effective: The shear pins used in pin couplings are relatively inexpensive compared to other coupling components. In the event of a failure, replacing the damaged pins is a cost-effective solution, avoiding more significant repairs to the main equipment.

- 4. Easy Replacement: After shearing, the damaged pins can be quickly and easily replaced. This leads to reduced downtime and lower maintenance costs in the long run.

- 5. Versatility: Pin couplings are suitable for a wide range of applications, including pumps, compressors, fans, and other industrial machinery. Their ability to handle varying operating conditions makes them versatile in different environments.

- 6. Shock Load Absorption: Pin couplings can absorb and dissipate shock loads effectively. The shear pins act as a buffer, protecting the equipment from sudden impacts or overloads.

Despite their numerous advantages, it is essential to consider the limitations of pin couplings as well. They have lower torque capacities compared to some other coupling types, such as gear couplings or rigid couplings. Additionally, the need to replace shear pins after each failure may lead to more frequent maintenance requirements in applications with frequent overloads or misalignments.

In conclusion, pin couplings provide reliable torque transmission and safety features, making them a valuable component in various mechanical systems. Their ability to protect against overloads and accommodate misalignments makes them a practical choice in a wide range of industrial applications.

editor by CX 2024-05-02

by

Tags:

Leave a Reply