Product Description

Product Description

Frame scaffolding is also called tubular steel frame scaffolding, door style frame scaffolding, is a long established modular frame scaffolding system serving as working platform for construction and decoration purposes, which is composed of main frames, catwalk or walk board, braces or cross braces, brackets, coupling pins of spigot, guardrails and sometimes casters, etc.

| Pic. | Item | A (Width) | B (Height) | |

| Main Frame

Outer tube: 42*2.2mm/2.0mm/1.8mm Inner tube: 25*1.5mm/1.8mm/2.0mm |

1219mm | 914mm | ||

| 1219mm | 1219mm | |||

| 1219mm | 1524mm | |||

| 1219mm | 1700mm | |||

| 1219mm | 1930mm | |||

| 914mm | 1219mm | |||

| 914mm | 1524mm | |||

| 914mm | 1700mm | |||

| 914mm | 1930mm | |||

| H Frame

Outer tube: 42*2.2mm/2.0mm/1.8mm Inner tube: 25*1.5mm/1.8mm/2.0mm |

1219mm | 914mm | ||

| 1219mm | 1219mm | |||

| 1219mm | 1524mm | |||

| 1219mm | 1700mm | |||

| 1219mm | 1930mm | |||

| 914mm | 914mm | |||

| 914mm | 1219mm | |||

| 914mm | 1524mm | |||

| 914mm | 1700mm | |||

| 914mm | 1930mm | |||

| Item | A (width) | B (height) | C (length) | |

| 1829mm | 1219mm | 2198mm | ||

| 1219mm | 1219mm | 1724mm | ||

| 1829mm | 914mm | 2045mm | ||

| 1829mm | 610mm | 1928mm | ||

| 1219mm | 610mm | 1363mm | ||

| Item | Size | |||

| Joint Pin | 36*1.5*225mm | |||

| 36*1.2*225mm | ||||

| 36*1.0*225mm | ||||

Packaging & Shipping

Application

Company Profile

HangZhou CHINAMFG Industry Co., Ltd, with an investment of U.S. Dollars of 8 million, is a professional manufacturer engaged in the design, production & sale of scaffolding systems.

1. Location: HangZhou CHINAMFG is leading scaffolding manufacturer, located in HangZhou, ZheJiang Province, the raw material basement.

2. Team: We have professional team for sale, project design and construction.

3. Main products: Ringlock Scaffolding, Frame Scaffolding, Steel Plank, Catwalk, Ladders, Pipe & Clamp, Steel Prop, etc.

4. Production capacity: 7000-10000 Tons/month.

5. Loading capacity: 8-12 containers/day.

6. Delivery time: 10-15 days for 3-5 containers.

Fast delivery to satisfy your urgent project demand.

FAQ

Q1: Are you a factory or trading company?

A: We are a factory specializing in manufacturing scaffolding material.

Q2: Where is the loading port?

A: ZheJiang (Xihu (West Lake) Dis.g) Port.

Q3: What’s the MOQ of the product?

A: Different item has different MOQ. Normally one Container is preferred.

Q4: What certificates do you have?

A: We have ISO 9001, SGS certification.

Q5: Can I get some samples?

A: Yes, but usually the customer will pay for the cost and freight charges.

Q6: Do you have an OEM service?

A: Yes. We can provide OEM and ODM services as your requirements.

Q7: How long is the production cycle after ordering?

A: General it is about 15-30 days, according to different quantity requirement.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Steel |

|---|---|

| Structural Style: | Multi-Pole Scaffolding |

| Framework: | Combined Scaffolding |

| Supporting Mode: | Projecting Scaffolding |

| Lapping Form: | Full Scaffolding |

| Scaffolding Part Type: | Scaffolding Frames |

| Customization: |

Available

| Customized Request |

|---|

Are There Any Safety Considerations When Using Pin Couplings in Rotating Machinery?

Yes, there are several safety considerations to keep in mind when using pin couplings in rotating machinery. These considerations are essential to ensure the safe and efficient operation of the equipment and to protect personnel working in the vicinity. Here are some key safety points to consider:

- Guarding: When installing pin couplings, it is crucial to provide adequate guarding around the coupling area. This helps prevent accidental contact with the rotating coupling components, such as pins and hubs, which could cause severe injuries.

- Maintenance and Inspection: Regular maintenance and inspection of the pin coupling are vital to identify any signs of wear, misalignment, or damage. Any worn or damaged components should be replaced immediately to prevent coupling failure, which could lead to sudden equipment shutdown or safety hazards.

- Proper Alignment: Ensuring precise alignment of the connected shafts is crucial to the safe operation of the pin coupling. Misalignment can lead to increased stresses and premature wear on the coupling components, resulting in potential failures.

- Torque and Speed Limits: Adhering to the manufacturer’s recommended torque and speed limits for the pin coupling is essential for its safe operation. Exceeding these limits can lead to overloading and failure of the coupling.

- Environmental Considerations: Take into account the operating environment when selecting a pin coupling. Extreme temperatures, corrosive atmospheres, or harsh conditions may require special materials or coatings to ensure the coupling’s integrity and prevent premature failure.

- Training and Awareness: Operators and maintenance personnel should receive proper training on the safe handling, installation, and maintenance of pin couplings. Awareness of potential hazards and safety protocols is crucial for the safe use of rotating machinery.

- Emergency Shutdown: Install emergency shutdown systems that can quickly stop the rotating machinery in case of any safety concerns or abnormal conditions.

- Compliance with Regulations: Ensure that the use of pin couplings complies with all relevant safety and industry regulations and standards.

By taking these safety considerations into account and implementing proper safety measures, the use of pin couplings in rotating machinery can be done safely and effectively, mitigating potential risks and ensuring a safe working environment for personnel.

Role of Pin Coupling in Reducing Downtime and Maintenance Costs

A pin coupling plays a crucial role in reducing downtime and maintenance costs in various mechanical systems and power transmission applications. Its design and features contribute to improved reliability and ease of maintenance, resulting in enhanced operational efficiency and cost savings. Here’s how pin couplings achieve these benefits:

1. Shock Absorption: Pin couplings are known for their ability to absorb and dampen shocks and vibrations generated during operation. By cushioning the impact of sudden loads or torque spikes, they protect the connected equipment from potential damage, reducing the frequency of unexpected breakdowns and downtime.

2. Misalignment Tolerance: Pin couplings can tolerate a certain degree of misalignment between shafts, such as angular and parallel misalignment. This flexibility allows for easier installation and alignment of equipment, saving time and effort during setup and reducing the need for precise alignment procedures.

3. Low Maintenance: Pin couplings are designed with simplicity in mind, often consisting of only two coupling halves connected by pins. This straightforward construction means fewer components that can wear out or require regular maintenance. Additionally, the flexibility of the pins helps reduce wear on the coupling and connected equipment, leading to longer maintenance intervals.

4. Easy Replacement: In the event of a failure or wear, pin couplings are relatively easy to replace compared to some other coupling types. The simplicity of their design allows for quick disassembly and reassembly, minimizing downtime during maintenance or replacement procedures.

5. Cost-Effective: The combination of low maintenance requirements and reduced downtime translates into cost savings for businesses. With fewer unexpected breakdowns and lower maintenance expenses, the overall cost of ownership for systems employing pin couplings can be more economical.

6. Reliability: Pin couplings are known for their reliability and durability. When properly selected and installed, they can provide long service life without frequent replacements, contributing to stable and consistent system performance.

By minimizing downtime, maintenance efforts, and associated costs, pin couplings are a preferred choice in various industrial applications. However, it is crucial to ensure that the pin coupling is correctly sized and installed, and regular inspections and maintenance are conducted to maximize its benefits and prevent premature failure.

Can Pin Couplings Handle Misalignment Between Shafts?

Yes, pin couplings are designed to accommodate a certain degree of misalignment between shafts in rotating machinery. They are considered flexible couplings, which means they can provide some degree of angular, parallel, and axial misalignment capability.

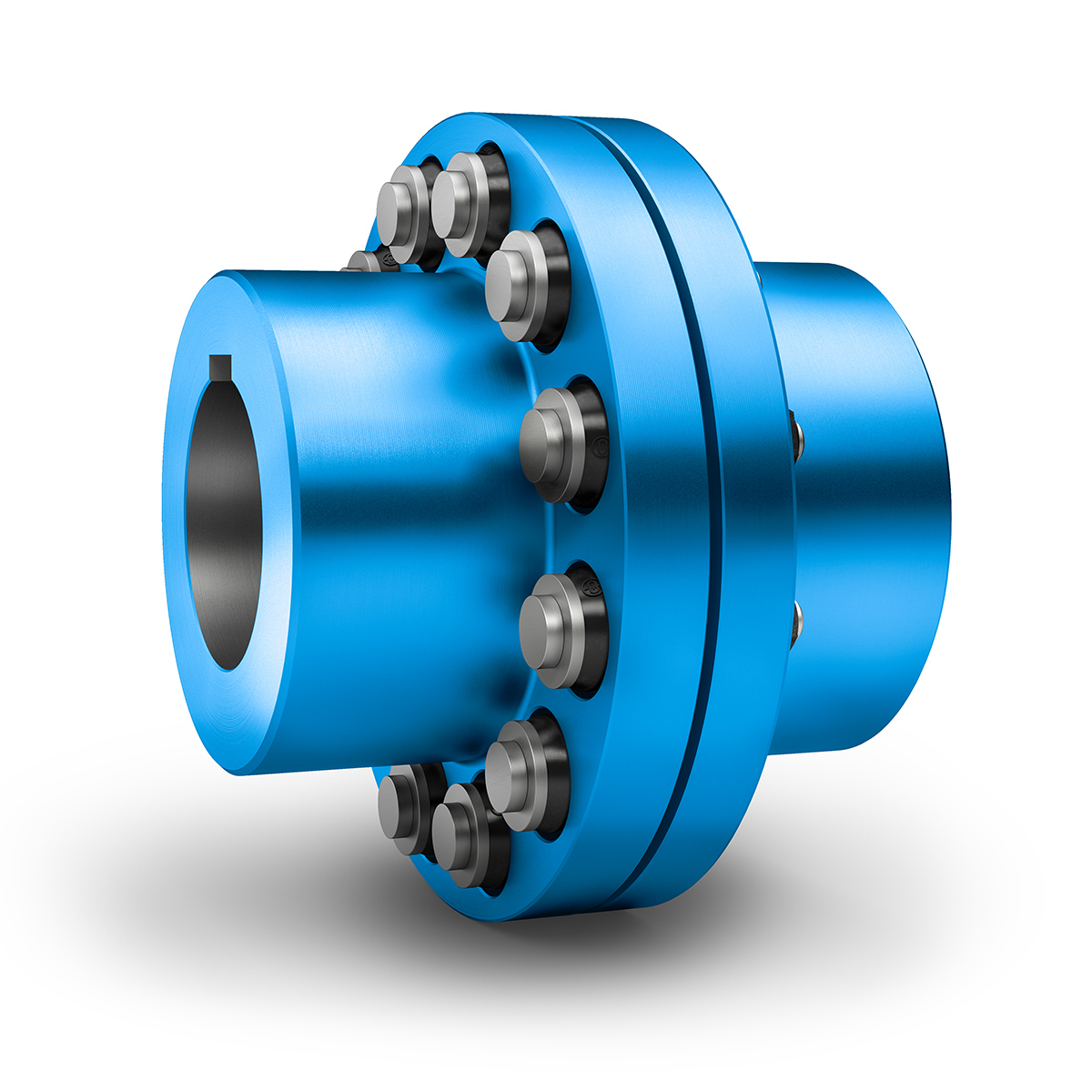

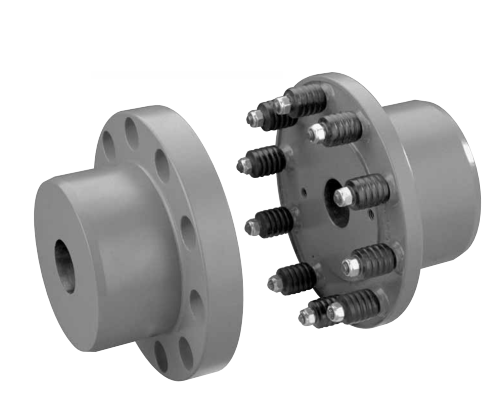

Pin couplings typically consist of two hubs, each connected to a shaft, and a central sleeve with pins that transmit torque between the hubs. The pins allow for a limited range of movement, which helps to compensate for slight misalignments between the shafts.

The angular misalignment capacity of a pin coupling is achieved through the bending of the pins. When the shafts are misaligned at an angle, the pins on one side of the coupling experience bending while those on the opposite side are in tension. The pins are designed to withstand these bending and tension forces within their elastic limits, ensuring proper functioning and longevity of the coupling.

Similarly, the pins can accommodate parallel misalignment by sliding within the pin holes of the coupling’s central sleeve. This sliding action allows the hubs to move slightly relative to each other, compensating for any offset between the shafts.

However, it is essential to note that pin couplings have limitations in terms of the amount of misalignment they can handle. Excessive misalignment beyond their specified limits can lead to increased wear on the pins and other coupling components, reducing the coupling’s effectiveness and potentially causing premature failure.

While pin couplings are suitable for applications with moderate misalignment requirements, they may not be the best choice for applications with significant misalignment or where precise alignment is critical. In such cases, more flexible couplings like gear or elastomeric couplings may be more appropriate.

Overall, when considering the use of pin couplings, it is essential to carefully evaluate the specific misalignment requirements of the application and select a coupling that can adequately accommodate those misalignments while ensuring reliable and efficient power transmission.

editor by CX 2024-04-22

by

Tags:

Leave a Reply